Well, both hydraulic motors and hydraulic pumps are correlative as they can be interchanged. Nevertheless, these two equipment have different directions of use and they hold different structural variations. A high-speed hydraulic motor like Kawasaki SX has similar basic structure characteristics as those of hydraulic pumps. However, the hydraulic pump has a valve distributor that can’t flow backward. On the contrary, the hydraulic motor has no valve distributor.

Likewise, there are other differences between these two.

Let’s find out!

Table of Content

- What is a Hydraulic Motor?

- What is a Hydraulic Pump?

- What Is the Difference Between Hydraulic Motor and Hydraulic Pump?

- Conclusion!

What is a Hydraulic Motor?

A hydraulic motor is also known as a standardized actuator. It converts hydraulic flow and pressure into angular displacement and torque. This movable equipment is used in a hydraulic cylinder. In a more all-inclusive knowledge, hydraulic motors can operate in hydropower. However, this term has been polished to specify only motors that make use of hydraulic fluid as a piece of their concluded hydraulic circuits.

What is a Hydraulic Pump?

A hydraulic pump can be described as a mechanical power origin, which transforms mechanical power into hydraulic energy. The hydraulic pumps are used in hydraulic drive systems. By generating flow with sufficient power, it overcomes the pressure generated from the pump outlet’s load. While performing an operation, a hydraulic pump produced a vacuum right at the pump inlet, and that forces the liquid to move through an inlet line into the pump from the reservoir.

What Is the Difference Between Hydraulic Motor and Hydraulic Pump?

In essence, hydraulic pumps convert the mechanical kinetic energy into hydraulic energy, whereas the hydraulic motor works on the opposite principle.

A hydraulic pump is attached to prime moves with the pump shaft with no extra radial load. And the hydraulic motor is connected to the load via pulleys, sprockets and gears. So its main shaft can carry an extended radial pressure.

A hydraulic pump features a vacuum in its low-pressure chamber. It is more effective at oil absorption and anti-captivation capability. Even the suction nozzle is typically more substantial than its nozzle for high pressure. But, a hydraulic motor doesn’t require any of these.

Even hydraulic motors require both negative and positive revolution, which allows the internal structure of the motor to be symmetrical. Whereas, hydraulic pumps revolve in a single direction, which opposes the demand of such a requirement.

A hydraulic motor has a more voluminous speed range, which can rearrange from lubrication mode to hearing form. A hydraulic motor requires a low, stable speed, while others require variable brake and speed.

Hydraulic motors require a large amount of start-up torque in order to reduce the static friction confronted during start-up. They also require enough start-up torque when there is a case of pressure fluctuation. On the contrary, hydraulic pumps have to be integrally self-priming.

Conclusion!

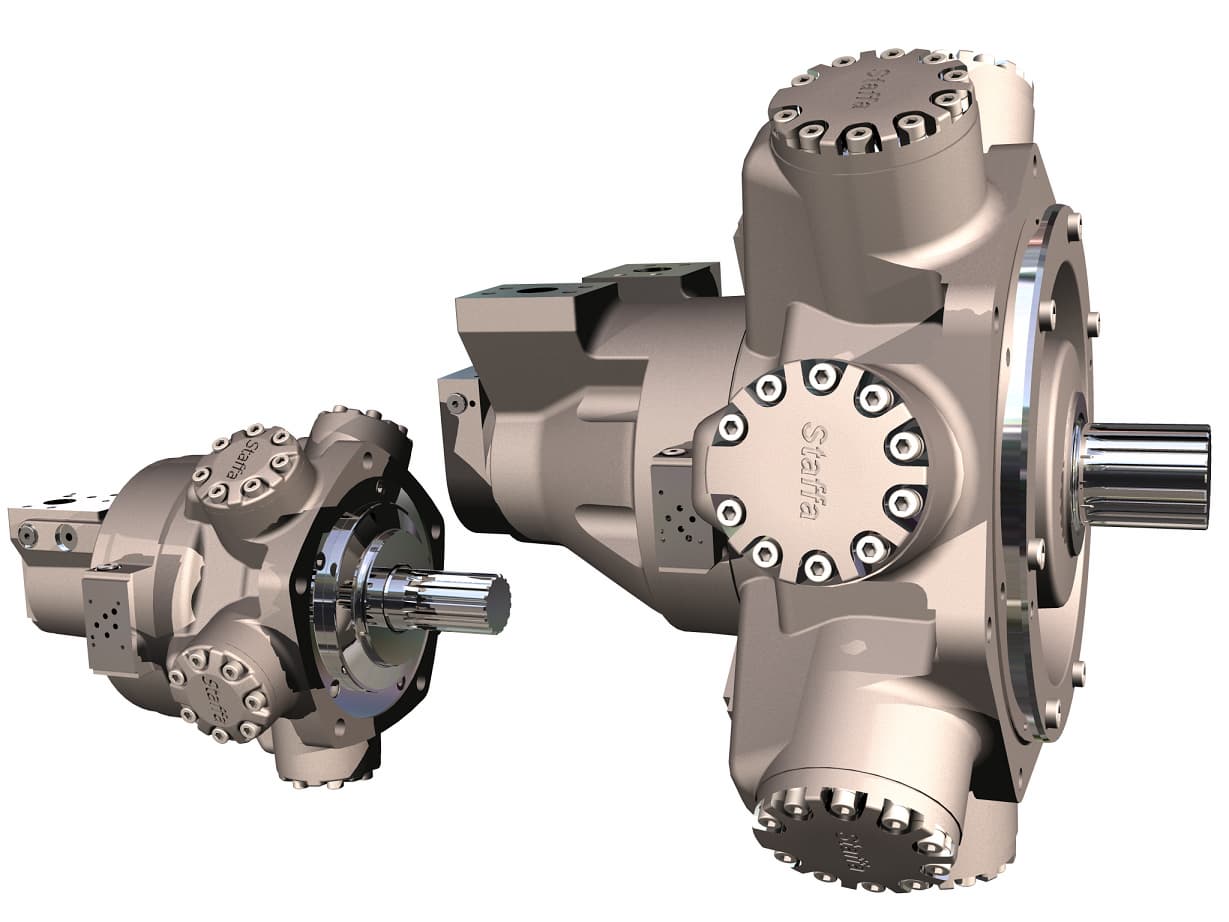

Now, you’re aware of the basic difference between a hydraulic motor and a hydraulic pump. Whether you’re thinking about buying a hydraulic motor and hydraulic pump of Staffa HMKC, you must hire a professional for executing the mechanical operations. If you’re looking to get your hydraulic pumps or hydraulic motors, why not contact the experts of Allgrind.